You have all winter. Go nuts.Personally I’d rather ride it as is because I’m not sure I have the skill set to go much further. Plus need to grab shims. I covered up the internals to keep any dust from going in so have time for some more research.

Although I did notice a discolouration on one valve. The black edges were worn down to a diff colour underneath.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve Clearance Check

- Thread starter mimico_polak

- Start date

Priller

Well-known member

Personally I’d rather ride it as is because I’m not sure I have the skill set to go much further. Plus need to grab shims. I covered up the internals to keep any dust from going in so have time for some more research.

Although I did notice a discolouration on one valve. The black edges were worn down to a diff colour underneath.

If it's me, I'm changing everything that's out of spec, which appears to be half your valves (especially as they're too tight, not too loose). You've checked them for a reason, might as well get them right, and as @Wingboy says, you have time. The real point of no return is pulling the cams, but as long as you're careful about recording how it was as you pull it apart, it's just a matter of being slow and methodical, and quadruple checking before you put the valve cover back on.

(The key step I missed when I did mine last winter was not rechecking the index marks after cycling the motor by hand to make sure valves and pistons didn't fight. The gears on the cams in the RC51 are split, so what looked closest to lined up when loosely torqued down ended up being a tooth off.)

You'll have to pull the old shims to know what you need. Another issue I had was my cheap Motomaster digital micrometer showed my old shims as being slightly thinner than marked. I ordered new ones based on that, but noticed the new ones showed thin, too. Turns out the micrometer wasn't accurate, and a double check with a nicer unit showed all exactly as marked, requiring another trip to the Honda dealership to get things bang on with a couple. It's a bit more money, but Honda sells shims with finer sizing than the shim kits you can buy, and I figure for the time taken, it's worth a couple bucks to get as close to ideal as possible.

What is ideal? Middle of the range would probably ideal for most. Loose would probably be ideal for someone that wants to extend intervals. Tight can increase power. Iirc I liked tight intake and loose exhaust when I played around before. Made the engine a lot more fun. Still within spec but just playing around within the range.it's worth a couple bucks to get as close to ideal as possible.

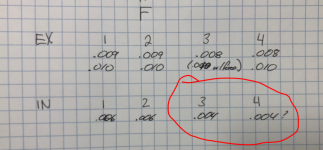

As you're this far into it I'd be changing out any shim that was tight and any shim that was at the threshold. Based on your numbers, this means 6 of 8 valves.

I really don't know the CB500X engine, but if this link (see URL) is accurate the process of pullings 4 bolts/pins to release the followers vs. pulling camshafts means changing out shims is dead simple. Key caveat is to not drop a shim into the guts of the engine, which applies to any shim change out.

The spec for the exhaust is 11 +- 1 and they are at 10/1000 now. Based on the shim in place now and available shim sizes for the exhaust valves I'd be trying to set them somewhere 11/1000 to 12/1000. For the 2 intakes that are at 6/1000 I'd be seeing if you could bump them closer to 7/1000 as long as you are in there.

Pull the pins, record the existing shims sizes for the valves being checked, replace the shims in their original place and then the pins and move on to check all the valves in this manner. Then you know what to order from Honda or what you need in a shim kit. Keep records of the shim size you change to as this will greatly simplify your next check/adjustment.

I really don't know the CB500X engine, but if this link (see URL) is accurate the process of pullings 4 bolts/pins to release the followers vs. pulling camshafts means changing out shims is dead simple. Key caveat is to not drop a shim into the guts of the engine, which applies to any shim change out.

CB500X Adjusting The Tappets

This is the final instalment of Ren's epic journey to the valves, tappets, followers and camshafts on the Honda CB500X. This time he finally gets to carry out the task he set out to do.

bikesandtravels.com

The spec for the exhaust is 11 +- 1 and they are at 10/1000 now. Based on the shim in place now and available shim sizes for the exhaust valves I'd be trying to set them somewhere 11/1000 to 12/1000. For the 2 intakes that are at 6/1000 I'd be seeing if you could bump them closer to 7/1000 as long as you are in there.

Pull the pins, record the existing shims sizes for the valves being checked, replace the shims in their original place and then the pins and move on to check all the valves in this manner. Then you know what to order from Honda or what you need in a shim kit. Keep records of the shim size you change to as this will greatly simplify your next check/adjustment.

I don’t think I would bother with the intake ones. I didn’t note your mileage but intakes generally don’t change nearly as much after break in as exhaust (where the heat/gases wear down the seats faster). I wonder was cylinder 2 maybe a little harder to get the feeler under the cam with less room to maneuver? Give it another try and see.

I don’t think I would bother with the intake ones. I didn’t note your mileage but intakes generally don’t change nearly as much after break in as exhaust (where the heat/gases wear down the seats faster). I wonder was cylinder 2 maybe a little harder to get the feeler under the cam with less room to maneuver? Give it another try and see.

Will try tonight, and thanks. These ones were a real pain in the *** to reach to get to...

The 0.004" reading is a guess as my feeler gauges go down to 0.005" but can wiggle them in partially...just not fully.

What? Your feeler gauges don't go to 1 or 1.5? Strange. The thin ones get a lot of use to stack to achieve increments you don't have a single gauge for.The 0.004" reading is a guess as my feeler gauges go down to 0.005" but can wiggle them in partially...just not fully.

The really thin ones can get stuck to each other.What? Your feeler gauges don't go to 1 or 1.5? Strange. The thin ones get a lot of use to stack to achieve increments you don't have a single gauge for.

So his .004 is 0.004+.0015? That would suck.The really thin ones can get stuck to each other.

What? Your feeler gauges don't go to 1 or 1.5? Strange. The thin ones get a lot of use to stack to achieve increments you don't have a single gauge for.

I find the .0005 is useless, too flimsy, the .00015 is much better. As an example, if I couldn't get a .007 in, but a .006 fit a bit loose, I'd use a .005 and a .0015 (effectively .0065) to see if the gap was closer to .006 or .007. All grist for the mill as existing shim size + available shim sizes will determine is a half thousandth determination has any real meaning in the process.

do yourself a favour and get a set of metric feeler gauges ... It's a pain to deal with the conversions, and these engines are all designed metric. I have to convert all of your measurements back to metric to make sense of them anyhow.

0.004" (evidently really a tight 0.005") is 0.10mm. My metric feeler gauge set goes tighter than that. Shims come in 0.05mm increments ... I'd go one step thinner on both of the two tight valves. Once you find out what thickness of shims you have in here, post up what they are. Someone around here might have some.

It looks like you don't have to remove camshafts or touch the timing chain or its tensioner ... just remove the rocker shafts from the end of the engine. Go for it. Not a hard job by the look of it.

0.004" (evidently really a tight 0.005") is 0.10mm. My metric feeler gauge set goes tighter than that. Shims come in 0.05mm increments ... I'd go one step thinner on both of the two tight valves. Once you find out what thickness of shims you have in here, post up what they are. Someone around here might have some.

It looks like you don't have to remove camshafts or touch the timing chain or its tensioner ... just remove the rocker shafts from the end of the engine. Go for it. Not a hard job by the look of it.

Priller

Well-known member

For me, ideal is the number in the book. As it's rare to hit that bang on with the way shims are sized, then it becomes the closest to spec on the loose side. If I'm on a street bike there are less risky ways to get a few horsepower, and if it's for racing I'd rather spend the cash to play with cam alignment and profiles, which still allows for ideal seating of the valves.What is ideal? Middle of the range would probably ideal for most. Loose would probably be ideal for someone that wants to extend intervals. Tight can increase power. Iirc I liked tight intake and loose exhaust when I played around before. Made the engine a lot more fun. Still within spec but just playing around within the range.

That's not to say you can't have fun with it with some bikes, I've just never owned one I wanted to take that chance with. Maybe my old Hawk GT with the threaded rockers, which made adjustment really easy, but I went down a different path with that one...

I always put a 45-60 degree bend in my feelers, maybe a third of their length from the tip, to make it easier to get around stuff.

Buddy works in a QA/QC shop so he took the feeler gauges to confirm the thicknesses of all of them. Put the pulling of shims on hold until I get those results back.

Alright results came in. Each feeler gauge is .0005" off. So according to my buddy at the QA/QC shop he said it's an acceptable error. These are calibrated tests done on the feelers.

Guess I'm pulling shims...after I pour the concrete in the laundry.

Guess I'm pulling shims...after I pour the concrete in the laundry.

I dunno what I expected a GL head to look like but it wasn't that. I guess that's to make it as flat as possible?Honda shims come in .025 mm sizes. The dealers around me seem to only stock .05 sizes but have no problem getting the smaller ones.

Anybody know what type of sealant I need to close things up again and button it up? I just realized I need a new gasket seal so will be ordering one this week prior to buttoning things up again.

Shop manual just states 'new sealant'.

Shop manual just states 'new sealant'.