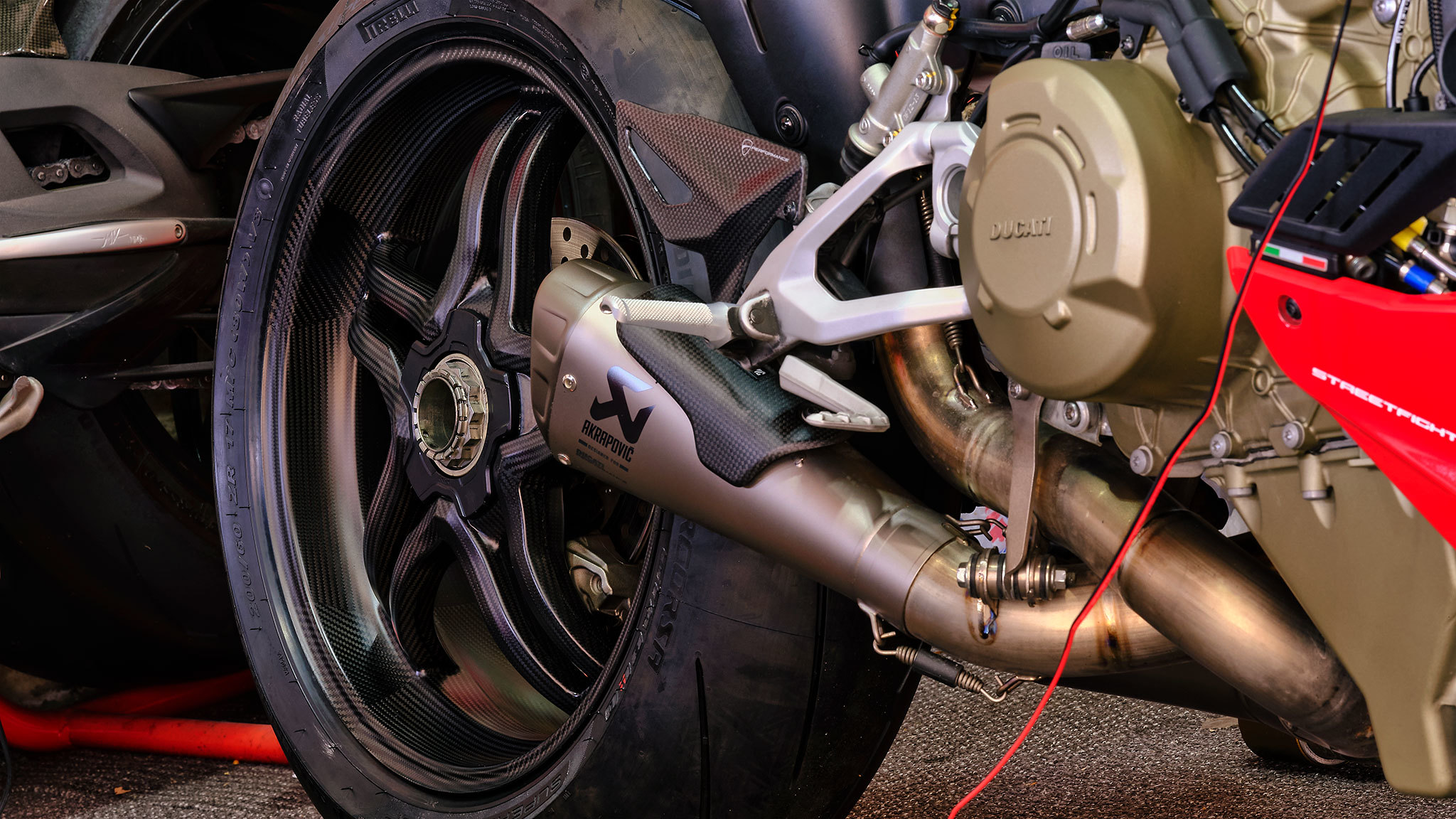

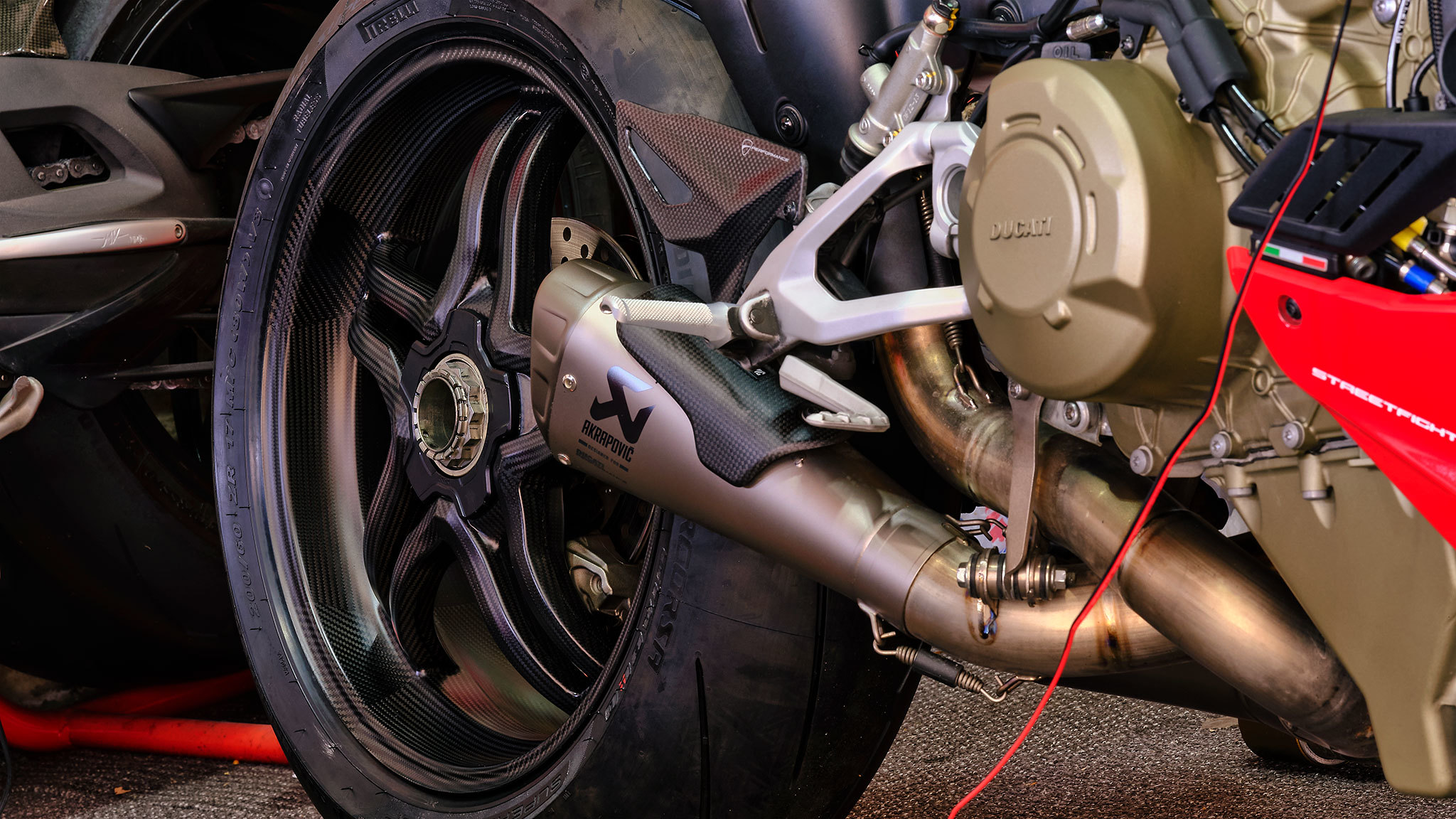

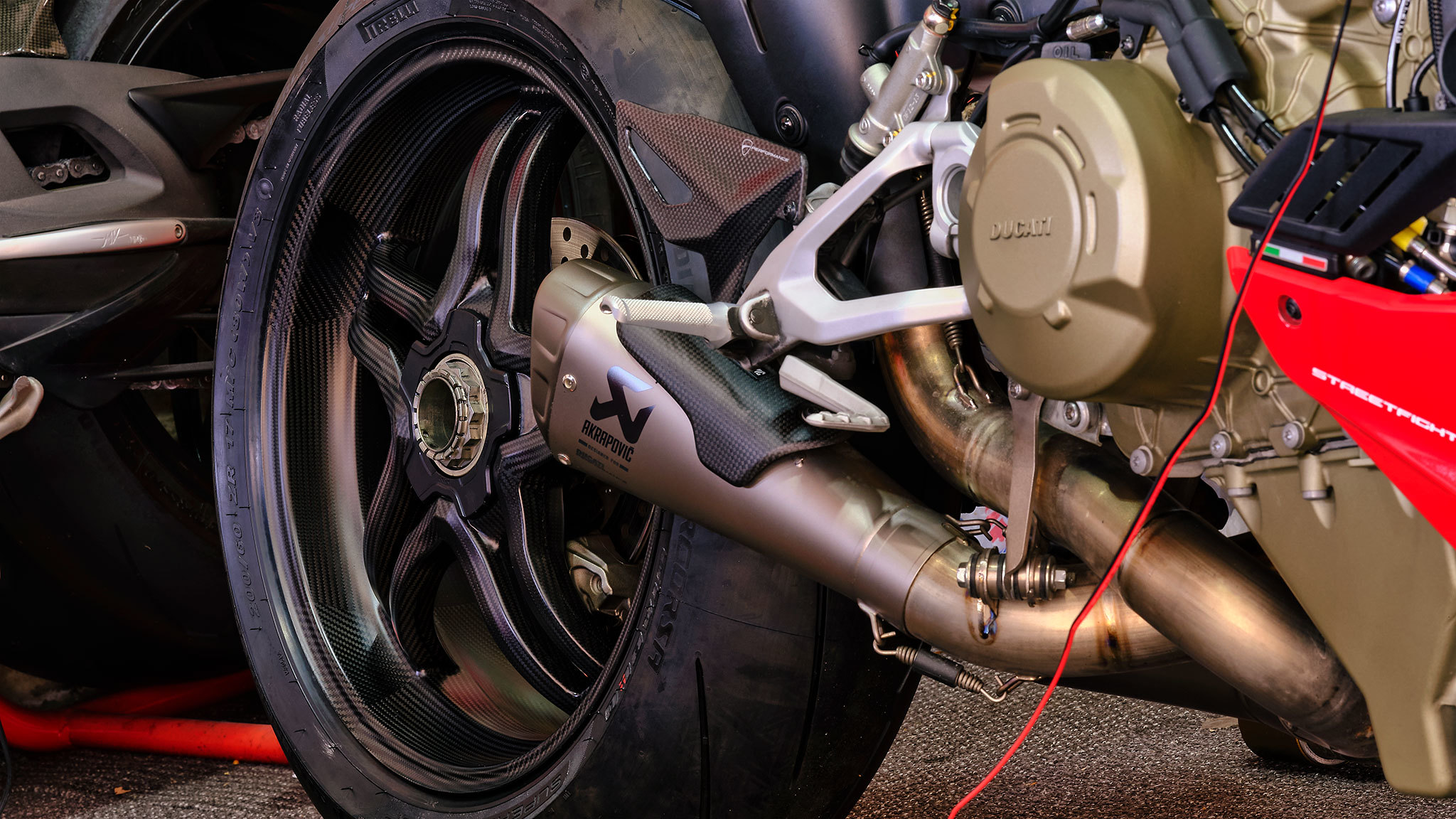

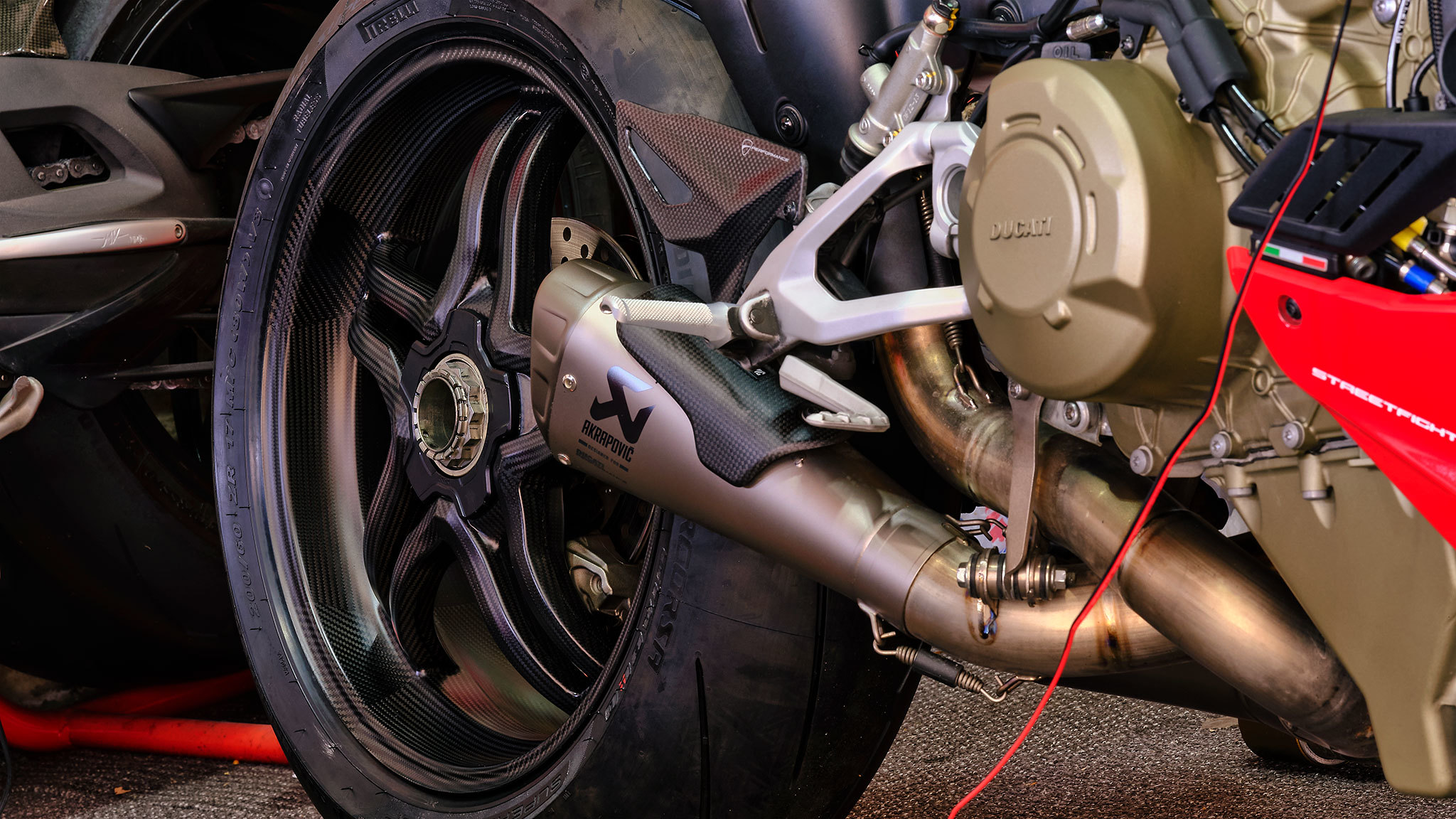

Installed a new pair of shoes on my bike. It made a very noticeable difference, the braking is amazing and switching directions is noticeably easier.

No more pics of that bike, I have low will power.Installed a new pair of shoes on my bike. It made a very noticeable difference, the braking is amazing and switching directions is noticeably easier.

What, is this a voting thing?Two valve motors win.

Is bitzz short for bitzzosaurus?What, is this a voting thing?

I'll take bevel springers for the win Alex.

Has heat been tried yet or just bigger hammers? Aluminum or steel swingarm? Painted?Took my swingarm to my neighour who has a few hotrods, looking for help to remove stuck needle bearings. He tried to knock them out with a hammer and rod and then tried to basically destroy the bearing so we could pull it out.

Unfortunately what is left is the outer sleeve (race?) of the bearing which I think is corroded in good. Because the swingarm bore narrows behind the bearing I can't get anything behind it to push it out, so I think I am stuck trying to pull it out. Unfortunately, the sleeve is only *maybe* one mm thick so I am worried it's going to be hard to get a puller to grip it strongly enough on the backside to pull it out.

Ordered a blind bearing puller set from Amazon and crossing my fingers.

That's what I was afraid of. I have quite a few triangular files, I think for sharpening woodworking saws - will they be able to cut through the hardened steel of the race? I also think there is a fairly high chance the thing is corroded to the bore.A puller will never get a grip. Get yourself a small triangular file and cut a groove in whats left of the bearing. Be careful, go slow, but when you cut through the bearing it will pop out from internal pressure.

That's what I was afraid of. I have quite a few triangular files, I think for sharpening woodworking saws - will they be able to cut through the hardened steel of the race?

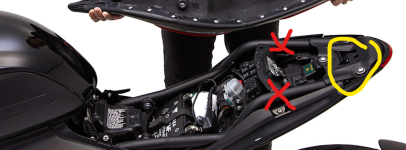

Nothing crazy but trying to figure out the best way to mount my newly acquired rokstraps.

love the things but my bike has the worst hook up capabilities. I can access the frame by removing the seat for one strap

Passenger footpegs are too far upfront

The x are where im strapping it currently

But i wonder if id be able to use what i circled in yellow and make it come out the back

Next season i might invest in some softbag but for this season im just trying to macgyver it a bit

View attachment 57406

Pullers are going to come tomorrow so I'll give them a shot. I think @bitzz will be right and there isn't enough of the race for them to catch, but if that fails I guess I go the files. I don't want to try the files now for fear that I might somehow compromise the ability of the pullers to work.Easy way to find out. It will either cut or skate across. Try a few different files if the first one skates.

Giving me ideas that, i could get some washers and screw that webbing in tooYou could grab a short length of 1" or 1.5" nylon webbing strap and two D rings. Lay the strap across your circled area, sandwiched down under the existing bolts and washers, with a D ring attached at both ends of the strap so that the rings protrude out just under the lip of the seat.

Reed valves . TRUMPED.What, is this a voting thing?

I'll take bevel springers for the win Alex.

... I don't get it.Reed valves . TRUMPED.

If it's a sleeved roller, it will have a vee cut lengthwise and the sleeve will be hard and springy. If this the case, you can find the cut with a small pick, then tap a chisel under the lip and it will peel free.Took my swingarm to my neighour who has a few hotrods, looking for help to remove stuck needle bearings. He tried to knock them out with a hammer and rod and then tried to basically destroy the bearing so we could pull it out.

Unfortunately what is left is the outer sleeve (race?) of the bearing which I think is corroded in good. Because the swingarm bore narrows behind the bearing I can't get anything behind it to push it out, so I think I am stuck trying to pull it out. Unfortunately, the sleeve is only *maybe* one mm thick so I am worried it's going to be hard to get a puller to grip it strongly enough on the backside to pull it out.

Ordered a blind bearing puller set from Amazon and crossing my fingers.

Run a bead of weld on the inside of it and it will almost fall out when it cools.Pullers are going to come tomorrow so I'll give them a shot. I think @bitzz will be right and there isn't enough of the race for them to catch, but if that fails I guess I go the files. I don't want to try the files now for fear that I might somehow compromise the ability of the pullers to work.

Yeah, one of my new favorites. I use to to heat bolts and stuck bearings with oxy/acetelene... today I use my MIG... faster and cheaper.Run a bead of weld on the inside of it and it will almost fall out when it cools.

Sent from the future