A friend did his kitchen with surplus cabinets he bought cheap at an auction. Choice is limited and it only works if you buy a bigger set than you need and use the excess in the garage or laundry.I ripped out over 400 kitchens (yes over 400) when I worked for Habitat. When we got a very large kitchen it had great potential for making up a slightly smaller kitchen. Counter tops would usually not match the new layout so there's that, but we had high end kitchens that you could buy for pennies on the dollar. Many people would come back with pics showing how they worked them into their layout.

I would not totally disregard the possibility of used cabinets.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Enough of COVID...what are you doing to the house?

- Thread starter mimico_polak

- Start date

Mad Mike

Well-known member

I've done that on a couple of restorations. It's not hard to find high-end kitchens getting ripped out big houses. They usually sell for $500-1500 and often include granite. A month ago I picked up an Ikea kitchen with approx 24' of uppers and 24' lowers, 4 glass doors, granite tops with under mounted sink, and a granite island for $1500. The kitchen was put in a year back, part of the old homeowner's effort to jazz up a 50-year-old house before he sold it. The new owners hated the idea of an Ikea kitchen, so out it went. Will be in the place up north soon.That may work for something like mm's project but for a whole kitchen it's a rough go imo. Layout really matters. Trying to make a collection of cabinets work in your space is often more trouble than it's worth and even if you could get most of the kitchen laid out that way there are often a few cabinets that you want that you dont have and getting those custom made to match could exceed the cost of the ikea kitchen.

I'm always surprised that custom cabinets don't have an easier way to find the manufacturer. Our old house had shaker style doors but of course a different style than everything I could find. I wanted to add a matching pantry but couldn't find people willing to match. They wanted to build their standard similar design. I get it but if I could find a label somewhere accessible on the existing cabinets, the original manufacturer should have been able to easily bang out my project. Nothing inside any box, Nothing in dishwasher cavity, nothing behind kickplate or on bottom of boxes. Maybe there is something on the backs but if I've dropped them to look, they aren't going back up.I've done that on a couple of restorations. It's not hard to find high-end kitchens getting ripped out big houses. They usually sell for $500-1500 and often include granite. A month ago I picked up an Ikea kitchen with approx 24' of uppers and 24' lowers, 4 glass doors, granite tops with under mounted sink, and a granite island for $1500. The kitchen was put in a year back, part of the old homeowner's effort to jazz up a 50-year-old house before he sold it. The new owners hated the idea of an Ikea kitchen, so out it went. Will be in the place up north soon.

Things is I basically have all the cabinets here...I would in theory just need to take them out, re-install them to a new layout and add a small handful of new boxes to fill any voids created. Doesn't seem like much of a difference from what the group is recommending with getting used cabinets.

Just need to make sure they come out in a proper manner, and the doors are labelled accordingly to the cabinet that they came from.

Just need to make sure they come out in a proper manner, and the doors are labelled accordingly to the cabinet that they came from.

I think that is because custom cabinets are not all that custom. They have jigs set up for a handful of styles rinse and repeat. My guess is the original manufacturer, if still in business, may not even make that style anymore. And more importantly no real pride in manufacturing....Our current cabinets (guessing 1970s) has the manufacture name in each drawer.I'm always surprised that custom cabinets don't have an easier way to find the manufacturer. Our old house had shaker style doors but of course a different style than everything I could find. I wanted to add a matching pantry but couldn't find people willing to match. They wanted to build their standard similar design. I get it but if I could find a label somewhere accessible on the existing cabinets, the original manufacturer should have been able to easily bang out my project. Nothing inside any box, Nothing in dishwasher cavity, nothing behind kickplate or on bottom of boxes. Maybe there is something on the backs but if I've dropped them to look, they aren't going back up.

Today, the boxes are usually not much better than flat pack, same or similar materials (melamine wrapped particle board/MDF). Most cabinets are standard sizes with maybe a few they sized to fit. The faces, doors and gables are all I see that is in anyway "custom and are made of wood".... with maybe the exception of the very top end, even then. The word "custom" is used loosely.

*******

My plan is to make my own boxes, faces and doors. Cabinet making is not rocket surgery (I have made cabinets before).... the ability to measure and cut a straight line on a table saw (basic woodworking skills).... some tools like a dado blade, router/shaping table. Proper clamps... Nothing all that special. Prior to COVID I would be about $1000 in materials to do a decent sized kitchen , 2K+ right now. Still cheaper than Ikea.

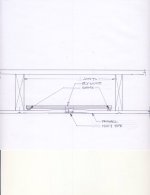

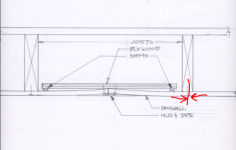

This is the detail I use on ceilings. The ends of the drywall get a fake taper.That's a bad situation with light on a glancing incidence. If you want it perfect, you need an old guy to skim the whole thing and give you a level five finish. It wont be cheap. Likely mid four figures. Theres a reason most houses have popcorn ceilings.

Attachments

I have never considered doing our own work for the cabinets. My dad literally has all the tools available in his shop to do the work. LoL

I should push him to retire and get cracking!

I should push him to retire and get cracking!

Fancy. I like it.This is the detail I use on ceilings. The ends of the drywall get a fake taper.

so anybody doing a custom right now , paint grade mdf doors are $18sqft , so $60 per door 16"x30" , solid wood $100 per door and the average kitchen has 20 doors.

5/8-3/4 wht Melamine ( TFL now, nobody calls it melamine) is $30 sht , kitchen takes average 10 shts , if you put in prefinished UV maple or birch ply your at $90.00 sht, Blum softclose hinges $3.00 X 40 , 8 drawers , well birch dovetail boxes are about $100 ea . And we havent put any pulls or handles on this thing yet.

Its a quick trip to 5K and you havent put in the revashelf stuff the wife likes , garbage pullouts , recycle bins .

And this is kitchen basic , its also about $1000 to paint all those doors, start asking for rift white oak panels and AA cherry with not gum spots and you added another 5k to the project.

5/8-3/4 wht Melamine ( TFL now, nobody calls it melamine) is $30 sht , kitchen takes average 10 shts , if you put in prefinished UV maple or birch ply your at $90.00 sht, Blum softclose hinges $3.00 X 40 , 8 drawers , well birch dovetail boxes are about $100 ea . And we havent put any pulls or handles on this thing yet.

Its a quick trip to 5K and you havent put in the revashelf stuff the wife likes , garbage pullouts , recycle bins .

And this is kitchen basic , its also about $1000 to paint all those doors, start asking for rift white oak panels and AA cherry with not gum spots and you added another 5k to the project.

Mad Mike

Well-known member

That's a great technique if your rooms are more than 12' across for the butt joints, unnecessary work on the tapered sides. I do something similar but easier -- sister a 2x4 to one joist raising the sister by 1/4". Set the butt seam to ne in the middle of the sister, screw both butt ends to the joists then taper in by screwing to the sister.This is the detail I use on ceilings. The ends of the drywall get a fake taper.

If you have 9' ceilings, you can coffer and eliminate taping altogether.

Then you don't have a tapered joint. You can't finish flat drywall. You either fill a valley or make a mountain. The sides of the sheet are tapered so you can fill a valley but the ends make a mountain without tricks. In some situations, the mountain isn't easily visible, in situations like HW, you need to pull out all the tricks or accept mediocrity.What I do is cut the sheet to end at the closest joist. This way I have sheets meeting at the joist, and don't need to worry about the support in the middle.

View attachment 52914

Not sure what to say...but it comes out pretty good and we've never had an issue.

So this plywood shim goes the full height / length of the sheet at each joint?

So this plywood shim goes the full height / length of the sheet at each joint?

@crankcall what wood is typically used for cabinets? Boxes and doors? Or just doors?

I rip a sheet of plywood into 12" by 48" strips and the shims can be any thin scraps, 48" long, about the thickness of a popcicle stick. While a good drywaller can taper a joint to almost invisible this is easier for an amateur and is dead flat. No biggie if the ceiling is goint to be popcorn but if higher gloss is required it's worth some scrap plywood.Not sure what to say...but it comes out pretty good and we've never had an issue.

So this plywood shim goes the full height / length of the sheet at each joint?

@crankcall what wood is typically used for cabinets? Boxes and doors? Or just doors?

All depends on what the finish look is . Most boxes are 5/8 TFL ( melamine) in higher end it’s always 3/4 . Plywood boxes in prefinished UV clear on maple or birch is very popular . Nobody likes to spray boxes if they can help it . People Pooh Pooh particle board but if stays flat and holds fasteners as well as veneer core plywood if you assemble correctly.

Doors these days are painted MDF , which stand up very well , you can get thermofoil and Gen2 vinyl wrap but it always looks lower end . Painted maple or birch look great but it’s hard to beat the look of painted mdf , no cracks in the finish at the joints .

When the boxes go together at a good shop they are doweled and screwed and glued , faster shops use glue and a 1 1/2 “ crown stapler .

You can buy glue that sticks to melamine , kliebert makes it , but actually a bead of clear silicone on the box joints with particle board screws and the next day a club won’t take it apart .

Sent from my iPhone using GTAMotorcycle.com mobile app

Your way is the way most are done. Nobbies way will be easier to smooth if your eye can run along the wall towards a light source. A master taper can skim the whole wall and fix it but that is far beyond my ability.Not sure what to say...but it comes out pretty good and we've never had an issue.

So this plywood shim goes the full height / length of the sheet at each joint?

Mad Mike

Well-known member

I like the Nobbie idea, but I'm not sure how hard it would be to fill and fair a 24" wide bow for the average handyman.Your way is the way most are done. Nobbies way will be easier to smooth if your eye can run along the wall towards a light source. A master taper can skim the whole wall and fix it but that is far beyond my ability.

I back cut butt seams a little, and find regular paper tape is easier to fair than glass tapes when the skim coat is thin.

Flat paint helps a lot.

Exactly. The key is getting an oversized kitchen and being able to then reconfigure some for your existing layout. If you can make it work the cost savings can be huge though.A friend did his kitchen with surplus cabinets he bought cheap at an auction. Choice is limited and it only works if you buy a bigger set than you need and use the excess in the garage or laundry.

AllistonGT

Well-known member

Few shops around are fully custom. Our cabinets are 100% custom. Never the same. As are the doors. We have no "line"of doors or limit to colours that can be chosen. It's whatever is specked by the Architect or designer. A "custom" shop that won't match an existing door, isn't a custom shop. That term is loosely used these days. Fact is most shops just assemble cabinets and finish. Doors and drawers are farmed out.I think that is because custom cabinets are not all that custom. They have jigs set up for a handful of styles rinse and repeat. My guess is the original manufacturer, if still in business, may not even make that style anymore. And more importantly no real pride in manufacturing....Our current cabinets (guessing 1970s) has the manufacture name in each drawer.

I know someone who just hired a custom shop to do their kitchen. Choice of 3 different whites, 4 door profiles. Guy says they are custom. Lol.

Our company name is nowhere to be found on our cabinets. We don't need to advertise.