Mad Mike

Well-known member

As we head into the offseason, it's time for projects and garage time. Most of us have tools, some too many, some never enough. How about sharing a little information on your stuff?

Post a tool (not your whole garage), let the rabble guess what it is. Or just tell us. If you have the same or alternative tool, reply with a pic of yours.

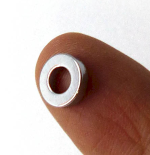

I'll start, I have one of these -- not used often but handy if you need one.

Post a tool (not your whole garage), let the rabble guess what it is. Or just tell us. If you have the same or alternative tool, reply with a pic of yours.

I'll start, I have one of these -- not used often but handy if you need one.