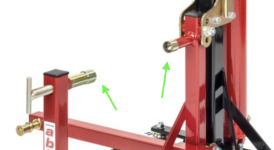

I have a lift which uses fittings that go into the swingarm pivot point on both sides. The vendor sells fittings for my road bike and I have these on order.

However, I also have three dirt bikes and an old 87 project bike for which the vendor does not list fittings. I have a tiny (Sherline) lathe designed for machining metal, but I have only ever used it to turn a few pens.

So, I need some bar stock to learn on. The ideal material would be easy to machine, and hopefully affordable as I expect to make lots of mistakes. Bonus would be that it has the properties needed for this application, but I'm willing to buy different stock once I'm ready.

I talked to a guy at Metal Supermarkets who recommended something he called "C12L14". I didn't know what to expect but it seemed expensive at $50/linear foot, for 2" diameter stock. I told him I'd be happy to buy offcuts but he didn't have any.

Any recommendations from the knowledgeable here as to what I should start off learning with, what I might want to use eventually, and where I might find cheap material to practice on? I considered visiting machine shops and asking to buy offcuts, but I don't know what material I even want.

However, I also have three dirt bikes and an old 87 project bike for which the vendor does not list fittings. I have a tiny (Sherline) lathe designed for machining metal, but I have only ever used it to turn a few pens.

So, I need some bar stock to learn on. The ideal material would be easy to machine, and hopefully affordable as I expect to make lots of mistakes. Bonus would be that it has the properties needed for this application, but I'm willing to buy different stock once I'm ready.

I talked to a guy at Metal Supermarkets who recommended something he called "C12L14". I didn't know what to expect but it seemed expensive at $50/linear foot, for 2" diameter stock. I told him I'd be happy to buy offcuts but he didn't have any.

Any recommendations from the knowledgeable here as to what I should start off learning with, what I might want to use eventually, and where I might find cheap material to practice on? I considered visiting machine shops and asking to buy offcuts, but I don't know what material I even want.