You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Stainless Steel braided brake lines at pro 6

- Thread starter Domon

- Start date

redridernl

Well-known member

This thread is relevant to my interests...

Hmmm.... I only buy from authorized Galfer dealers as listed on their website. Not to shortchange Pro6 (I hear they do great and I plan to see them for a thing or two soon) but brakes aren't something to be played around with.

It's just a braided line.....

Given a choice over Sandy making me a line, or having a Galfer line that was made by one of Kathy Lee Gifford's employee's i know which one i would prefer.

They did my first ever set of SS lines with anodized Earls fittings in 2001, back then I paid around $500 for front and rear installed....For the last 8 years or so I have been making my own, or buying kits and installing them myself. Its not rocket science and the hardest part is actually the bleeding. There is alot of money to be saved, cost for lines when I build them myself is under $200.

They did my first ever set of SS lines with anodized Earls fittings in 2001, back then I paid around $500 for front and rear installed....For the last 8 years or so I have been making my own, or buying kits and installing them myself. Its not rocket science and the hardest part is actually the bleeding. There is alot of money to be saved, cost for lines when I build them myself is under $200.

I think you can get kits out there for $100 which include front and rear

frekeyguy

Well-known member

I think you can get kits out there for $100 which include front and rear

Not Earl's....and not in 2001.

The $100 kits aren't worth it, the banjo/crimp points twist and they leak.

Not Earl's....and not in 2001.

The $100 kits aren't worth it, the banjo/crimp points twist and they leak.

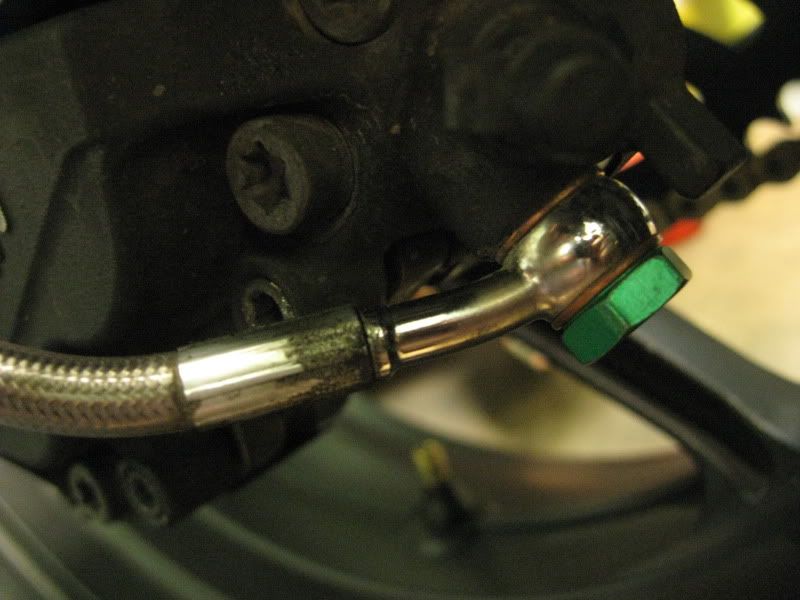

Exactly I prefer making my own lines with reusable fittings, those lines I had made in 2001 were used on 3 different bikes of mine after the initial purchase...Im still using some of the fittings today 10 years later! People say anodized aluminum fittings are no good, but these ones have been reused on many different bikes over the last 10 years. The bike has been down many times and you can even see there is actually rash on the fitting itself lol...So.....

Ive also had some pre made brand name lines start to leak at the fitting crimp, this was a brand new line....I had about 10 of them, and roughly %50 leaked. If this was a reusable fitting, I could just shorten the line a tiny bit and reuse it....Because its not the whole line and both fittings is garbage...

Build your own lines are a better investment IMO...If you mess up a 2 line pre made kit, you cant source the line separately, you would need to buy a whole new kit...Another big advantage is the ability to custom route the lines while your building them, if you have aftermarket clip-ons, rear sets, master cylinders etc etc pre made lines may or may not route or fit properly...For me this is always the case as I dont run OEM masters on any of my 3 bikes...

Last edited:

Exactly I prefer making my own lines with reusable fittings, those lines I had made in 2001 were used on 3 different bikes of mine after the initial purchase...Im still using some of the fittings today 10 years later! People say anodized aluminum fittings are no good, but these ones have been reused on many different bikes over the last 10 years. The bike has been down many times and you can even see there is actually rash on the fitting itself lol...So.....

Ive also had some pre made brand name lines start to leak at the fitting crimp, this was a brand new line....I had about 10 of them, and roughly P leaked. If this was a reusable fitting, I could just shorten the line a tiny bit and reuse it....Because its not the whole line and both fittings is garbage...

Build your own lines are a better investment IMO...If you mess up a 2 line pre made kit, you cant source the line separately, you would need to buy a whole new kit...Another big advantage is the ability to custom route the lines while your building them, if you have aftermarket clip-ons, rear sets, master cylinders etc etc pre made lines may or may not route or fit properly...For me this is always the case as I dont run OEM masters on any of my 3 bikes...

Hahahaha, are those compression fittings I see there? With Ferrules? I've used them in low pressure applications before but wouldn't have trust it on brakes. How are the reliability?

Hahahaha, are those compression fittings I see there? With Ferrules? I've used them in low pressure applications before but wouldn't have trust it on brakes. How are the reliability?

Yes they are a compression fittings with a ferrule used inside. Reliability is great, like I posted above Ive had those since 2001. Ive reused them as they were assembled in 2001 with no leaks for 10 years, some Ive just replaced the line or ferrule and again no leaks for years...

If a crimped line leaks you can try to have it re crimped but that rarely works, and who has a crimping tool at home? If a compression fitting leaks, you can simply tighten it more with regular open end wrenches. Or you can get a new ferrule for $1 and re build the line...If the line leaks you can replace the line....

Yes they are a compression fittings with a ferrule used inside. Reliability is great, like I posted above Ive had those since 2001. Ive reused them as they were assembled in 2001 with no leaks for 10 years, some Ive just replaced the line or ferrule and again no leaks for years...

If a crimped line leaks you can try to have it re crimped but that rarely works, and who has a crimping tool at home? If a compression fitting leaks, you can simply tighten it more with regular open end wrenches. Or you can get a new ferrule for $1 and re build the line...If the line leaks you can replace the line....

Doesn't the ferrule weaken the line? I've used those on hard pipes (not motorcycle related), they actually dig into the line. It however makes a clean air tight seal.

Do you get it at any hardware store?

Plus do you get SS lines that are resistant to brake fluid?

If so let me in on the little secret

Doesn't the ferrule weaken the line? I've used those on hard pipes (not motorcycle related), they actually dig into the line. It however makes a clean air tight seal.

Do you get it at any hardware store?

Plus do you get SS lines that are resistant to brake fluid?

If so let me in on the little secret

The fittings are made specifically for brake line....There are many brands, those ones are Earls, Goodridge, Galfer, etc all make them as well in plated steel or anodized aluimnum. Whatever brand fitting you buy, they will have a line that is to be used with it...They are all generally the same, nylon inner tubing with a SS over braid, and usually some kind of plastic protective coating...

Pretty much every motorcycle catalog has these parts listed in the brakes section, some stores like Riders Choice and Pro6 stock them. Sell the fittings by themselfs and the line by the foot...

Ive never had one dig into the line enough to cause a leak, the ferrules are either aluimnum or brass...As with everything if you assemble them properly and dont over tighten they will last forever...

There is a post on here somwhere from about a year ago, where I walk someone through the assembly of these fittings with pictures. It was their first time attempting it, and as far as I know they were successful...So its not that difficult

Last edited:

The fittings are made specifically for brake line....There are many brands, those ones are Earls, Goodridge, Galfer, etc all make them as well in plated steel or anodized aluimnum. Whatever brand fitting you buy, they will have a line that is to be used with it...They are all generally the same, nylon inner tubing with a SS over braid, and usually some kind of plastic protective coating...

Pretty much every motorcycle catalog has these parts listed in the brakes section, some stores like Riders Choice and Pro6 stock them. Sell the fittings by themselfs and the line by the foot...

Ive never had one dig into the line enough to cause a leak, the ferrules are either aluimnum or brass...As with everything if you assemble them properly and dont over tighten they will last forever...

Awesome, that just opened a door of possiblities for running my lines.

I have a bit of experience creating these fittings for an air tight seal, so thick fluids should be a breeze

Thanks Johnny

Last edited:

Red_Liner740

Well-known member

If aircraft uses exclusively aluminium ano'd fittings for low and high pressure EVERYTHING, than i'm sure its fine for low pressure brake fluid applications

If aircraft uses exclusively aluminium ano'd fittings for low and high pressure EVERYTHING, than i'm sure its fine for low pressure brake fluid applications

That compression fitting is the best thing invented for connections. I think there was a patent for it before it became widespread. Its a good way to connect metal-metal and metal-tubing. Its almost as the invention of the wheel, lol

That compression fitting is the best thing invented for connections. I think there was a patent for it before it became widespread. Its a good way to connect metal-metal and metal-tubing. Its almost as the invention of the wheel, lol

Compression fittings are used everywhere in almost every industry...I have air lines on my machines with them, hydraulic and grease lines on machines, household plumbing via compression fittings, etc etc

And I just solved a cost issue at work with compression fittings, our spray gun fluid line was getting clogged every 2 weeks......You can only buy the lines together fluid and air for around $40-50.....So instead I bought a 500' spool of hose, and reusable compression fittings...Now a new line only costs $10, and I can make them whenever I need them

Last edited: