So i bought and incomplete moped project and inherited the reasons why it didnt finish.

Among other things, the folks tried to widen the axle openings in the fork legs to accept an 11mm axle, which is generally an uncommon size but occurs frequently enough in the moped world to warratn the mod. Anyway they hacked up the holes pretty bad and on top of this the widened holes are now offset from the centre portion of where the (very obvious) round part of the fork leg would dictate the opening for the axle would be.

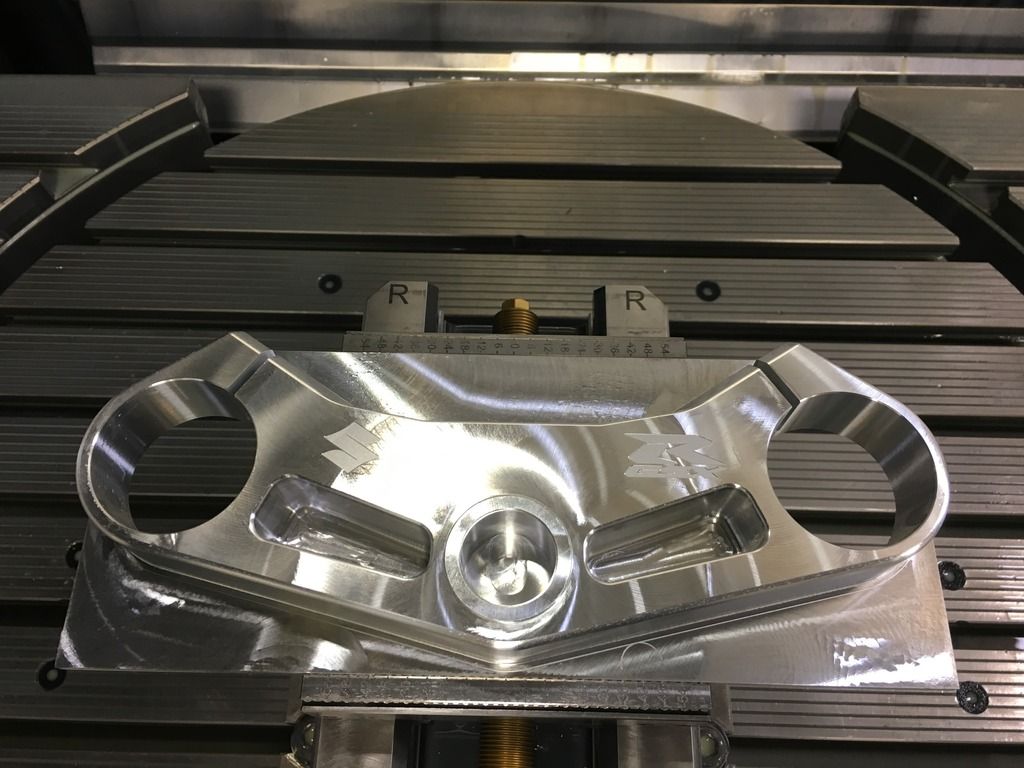

Somehow luck was on my side and I found copper/brass sleeves on ebay from china which are 13mm OD and 11mmID so i think i will go this route. the question is do I try to bore the holes with my mastercraft drill press or take it to my friendly neighbourhood obscenely expensive machine shop?

The forks are NOS suzuki K10 forks from 60s/70s. Theyre simple but hydraulic and of decent quality. Not expensive at all but equally uncommon.

Among other things, the folks tried to widen the axle openings in the fork legs to accept an 11mm axle, which is generally an uncommon size but occurs frequently enough in the moped world to warratn the mod. Anyway they hacked up the holes pretty bad and on top of this the widened holes are now offset from the centre portion of where the (very obvious) round part of the fork leg would dictate the opening for the axle would be.

Somehow luck was on my side and I found copper/brass sleeves on ebay from china which are 13mm OD and 11mmID so i think i will go this route. the question is do I try to bore the holes with my mastercraft drill press or take it to my friendly neighbourhood obscenely expensive machine shop?

The forks are NOS suzuki K10 forks from 60s/70s. Theyre simple but hydraulic and of decent quality. Not expensive at all but equally uncommon.