Can I get some guidance or confirmation on proper chain slack, or the proper way to measure the slack.

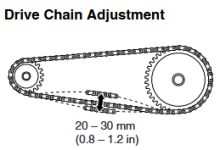

My service manual calls for 20mm-30mm of slack. It says to do it while the bike is on the side stand and NOT centre stand. Fine I got that.

I understand the slack needs to be measured at the centre point of the swing arm. This happens to be roughly at the point where the chain guard ends on the bottom side of the swing arm.

Should the lowest point of the slack be measured when the chain is in its natural position or should I be pressing it down as far as possible and consider this to be the lowest position.

As for the highest position, I am pushing the chain up to is furthest position.

The picture above has an an arrow indicating the slack of 20-30mm. I am understanding it as the dotted lines being the slowest and highest points that the chain can reach. Both being above and below is natural place.

I have watched a few videos and read some threads and they all seem to be unclear on this. The difference is probably minimal, therefore it may not matter but I want to be sure I am doing it right.

For the record, I am using a Motion Pro Slack Setter Tool.

So far I have applied the tool to the chain/swingarm, pushed the chain all the way up. Note the measurement off of the scale. Then press the chain all the way down, note the measurement and subtract the two to get the difference as my slack.

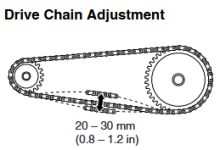

My service manual calls for 20mm-30mm of slack. It says to do it while the bike is on the side stand and NOT centre stand. Fine I got that.

I understand the slack needs to be measured at the centre point of the swing arm. This happens to be roughly at the point where the chain guard ends on the bottom side of the swing arm.

Should the lowest point of the slack be measured when the chain is in its natural position or should I be pressing it down as far as possible and consider this to be the lowest position.

As for the highest position, I am pushing the chain up to is furthest position.

The picture above has an an arrow indicating the slack of 20-30mm. I am understanding it as the dotted lines being the slowest and highest points that the chain can reach. Both being above and below is natural place.

I have watched a few videos and read some threads and they all seem to be unclear on this. The difference is probably minimal, therefore it may not matter but I want to be sure I am doing it right.

For the record, I am using a Motion Pro Slack Setter Tool.

So far I have applied the tool to the chain/swingarm, pushed the chain all the way up. Note the measurement off of the scale. Then press the chain all the way down, note the measurement and subtract the two to get the difference as my slack.