Priller

Well-known member

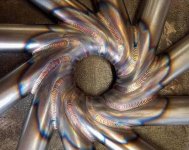

So I have an RC51 with a leaking tank, at the rear where a tilt sleeve is welded on to the tank via a bracket. It's a known issue that Honda was replacing under warranty once upon a time, but that ship has long sailed.

My understanding is that they tack welded the bracket to the bottom of the tank. Over time (and with heavy and full tanks being tilted back), the tack welds fail, resulting in cracks under the bracket. Because these cracks are still moving, any tank liner product will also fail eventually, so the only long-term fix is to weld the leak and also reinforce that part of the tank by completely welding around the bracket.

My issue is that no welder I've talked to thus far is willing to work on a gas tank, some saying a flat-out no, others saying they need a professional cleaning and certified letter to that effect. I can understand the reluctance to apply a spark near where fuel has been stored, but there must be someone who can clean and weld in one shop?

If anyone can recommend somewhere willing to take this on, I'd be very grateful...

My understanding is that they tack welded the bracket to the bottom of the tank. Over time (and with heavy and full tanks being tilted back), the tack welds fail, resulting in cracks under the bracket. Because these cracks are still moving, any tank liner product will also fail eventually, so the only long-term fix is to weld the leak and also reinforce that part of the tank by completely welding around the bracket.

My issue is that no welder I've talked to thus far is willing to work on a gas tank, some saying a flat-out no, others saying they need a professional cleaning and certified letter to that effect. I can understand the reluctance to apply a spark near where fuel has been stored, but there must be someone who can clean and weld in one shop?

If anyone can recommend somewhere willing to take this on, I'd be very grateful...