KenC

Well-known member

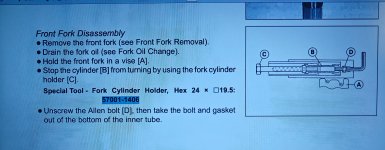

Apparently I need this tool to get my forks apart (2007 Kawi ZZR600).

Anyone have one or know of an alternative hack ?

I did manage to crack the bottom Allen bolt loose (before fork disassembly), but she's just spinning the inner cylinder now.

I did put it all back together to introduce some tension via the spring, but that's a no-go.

Anyone have one or know of an alternative hack ?

I did manage to crack the bottom Allen bolt loose (before fork disassembly), but she's just spinning the inner cylinder now.

I did put it all back together to introduce some tension via the spring, but that's a no-go.

Attachments

Last edited: