I would like to build a stand to support my project, an 87 CBR600F. Design criteria:

- Built out of wood, I have a full woodworking shop, and no welding skills or access to tools

- needs to be as small in both dimensions as possible as my workspace is quite li tied in space both lengthwise and width wise.

- Therefore, I am OK with it being 100% purpose built, designed for this bike only, so as to allow it to be maximally small

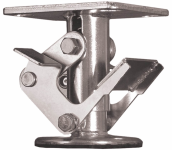

- will be on casters so that I can maximize my use of space. If I need to work to work on one side of the bike, I may need to push it against a wall. If I need to use my shop for something else, the bike and stand may need to be moved.

- I would like to use the space below the main deck of the stand for storage, again to maximize use of space.

- cheap as possible

I considered buying something like an Abba or Bursig stand but decided building would be much cheaper and could be an easy woodworking project. I do have a paddock stand but it doesn’t really support the easy moving to and fro.

Anyone here done something similar ? I’ve seen plans which are pretty simple, but probably designed for general purpose use.. My biggest questions are design related, like:

- how much bigger than the bikes footprint does a stand need to be ?

- how narrow can I make it before the lateral stability of the bike and stand is jeopardized?

- should I build it wide and long enough to handle a paddock stand on the main deck ?

- should it accommodate a triple stand? Or just a chock ?

- how high do I make it ?

- etc

- Built out of wood, I have a full woodworking shop, and no welding skills or access to tools

- needs to be as small in both dimensions as possible as my workspace is quite li tied in space both lengthwise and width wise.

- Therefore, I am OK with it being 100% purpose built, designed for this bike only, so as to allow it to be maximally small

- will be on casters so that I can maximize my use of space. If I need to work to work on one side of the bike, I may need to push it against a wall. If I need to use my shop for something else, the bike and stand may need to be moved.

- I would like to use the space below the main deck of the stand for storage, again to maximize use of space.

- cheap as possible

I considered buying something like an Abba or Bursig stand but decided building would be much cheaper and could be an easy woodworking project. I do have a paddock stand but it doesn’t really support the easy moving to and fro.

Anyone here done something similar ? I’ve seen plans which are pretty simple, but probably designed for general purpose use.. My biggest questions are design related, like:

- how much bigger than the bikes footprint does a stand need to be ?

- how narrow can I make it before the lateral stability of the bike and stand is jeopardized?

- should I build it wide and long enough to handle a paddock stand on the main deck ?

- should it accommodate a triple stand? Or just a chock ?

- how high do I make it ?

- etc