Literally, the story of my life.

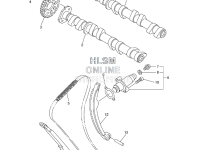

I was replacing the CCT on my FZ6. The hex bolt on the inner side wouldn't go all the way. Day 1 I tried and was in a bit of a hurry, but today I pulled everything out and did it from scratch, nope. The CCT looks like it is sitting tight but I wasn't sure if I could ride it, so I didn't disarm it and left the plate in. I didn't pay attention while disassembling the old one whether the bolt was fully in. Don't see a reason why it shouldn't be. Any suggestions here? Would it be ok if I rode it to a garage to have them look at?

Thanks!

I was replacing the CCT on my FZ6. The hex bolt on the inner side wouldn't go all the way. Day 1 I tried and was in a bit of a hurry, but today I pulled everything out and did it from scratch, nope. The CCT looks like it is sitting tight but I wasn't sure if I could ride it, so I didn't disarm it and left the plate in. I didn't pay attention while disassembling the old one whether the bolt was fully in. Don't see a reason why it shouldn't be. Any suggestions here? Would it be ok if I rode it to a garage to have them look at?

Thanks!